Description

PhoenixTM 6-Channel l Easy Thermal Profile for Paint & Powder Coating Application

The PhoenixTM Oven Temperature Profile System from the UK is the definitive answer for modern industrial coating. Designed to overcome the limitations of traditional systems, we empower your business with a professional Easy-to-use Oven Profiler that ensures sustainable quality through 7 Pillars of Excellence:

- High-Durability Alloy Construction: The data logger is encased in a premium aluminum alloy shell, ruggedly engineered to withstand high-temperature environments and heavy industrial use.

- Contamination-Free Paint Line Design: Fully compliant with global standards, our system is 100% Silicone-free, ensuring zero contamination and a flawless finish for every workpiece.

- Versatile Probe Selection: Specialized thermocouples are available for every surface type—metallic or non-metallic—guaranteeing high-precision data for even the most complex shapes

- Intelligent Cure Analysis Software: Our Easy-to-use Oven Profiler software features advanced “Cure Analysis,” providing precise data on paint maturity with unlimited user licenses and lifetime feature updates.

- Expert Consultation & Training: Gain a competitive edge with professional guidance and hands-on training from our veteran engineers, who bring decades of experience in the finishing industry.

- Rapid After-Sales Support: We offer comprehensive preventive maintenance and factory-standard calibration to ensure your equipment maintains world-class accuracy year after year.

- Local Stock for Business Continuity: With a full inventory of products and spare parts ready for immediate dispatch from our Thailand warehouse, your production remains seamless and uninterrupted.

"The Future of Thermal Profiling: Transcending Traditional Limits toward Excellence."

Getting Start with PhoenixTM 6-Channel System

Easy to connect, easy to profile—ready to track your oven instantly.

PTM1-006 Compact | 6-Channel Data Logger

Elevate Your Industrial Thermal Profiling Standards

Take your thermal analysis to the next level with the PhoenixTM 6-Channel Data Logger.

- Engineered with a robust Aluminum Alloy construction, this logger is built to be exceptionally strong and highly resistant to high-temperature environments.

- Unmatched Precision: Delivers high accuracy of ± 0.3°C across the entire operating range, ensuring your data is reliable and professional.

- Global Compliance: Supports efficient thermal profile analysis in full compliance with CQI-12 international automotive standards.

- The “Easy” Battery Solution: Eliminate the high maintenance costs and headaches of proprietary built-in batteries. The PhoenixTM architecture is intelligently designed to run on 2 x Standard AA Alkaline batteries.

- Zero Downtime: Because AA batteries are easy to find and easy to replace anywhere, you can swap them instantly. This keeps your production line moving, reduces downtime, and significantly slashes long-term maintenance expenses.

| Specifications | Details |

| Model | PTM1-006 Compact |

| Channels | 6 Channels (Type K Thermocouple) |

| Measuring Range | 0°C to 500°C |

| Accuracy | ±0.3°C |

| Resolution | ±0.1°C |

| Memory Capacity | 440,000 Data Points |

| Sampling Interval | User-selectable from 0.5 seconds to 60 minutes |

| Max Ambient Temp | Up to 80°C (Internal Logger Temperature) |

| Battery Type | 2 x ‘AA’ Standard Alkaline |

| Communication | USB Cable (Included) |

| Dimensions | 200mm (L) x 98mm (W) x 20mm (H) |

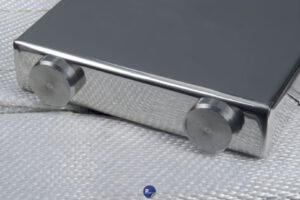

TS04 Series | Advanced Thermal Barrier for Painting & Coating

100% Silicone-Free: Premium materials ensure zero contamination and no surface defects—safe for all paint and powder coating lines.

Microporous Insulation: Superior heat protection that outlasts standard white rubber or low-quality fiberglass alternatives.

All-Metal Heatsink: High impact and heat resistance. Engineered to outlast plastic models for heavy industrial use.

| Product Attribute | Details |

| Product Code | TS04-113-3 |

| Body / Heatsink Material | Aluminum Alloy / Stainless Steel |

| Data Logger Capacity | 6 Channels |

| Dimensions (mm) | 113 (H) x 161 (W) x 320 (L) |

| Weight (kg) | 3.7 kg |

| Oven Temperature (°C) | Thermal Duration (Hours) |

| 100°C | 7.5 Hours |

| 150°C | 3.5 Hours |

| 200°C | 2.2 Hours |

| 250°C | 1.6 Hours |

| 300°C | 1.2 Hours |

High Grade Material: Rugged Construction. Engineering Excellence. Built to Last.

Lid Steel Plate: Quick magnetic probe attachment.

Handling Easy: Carry/hang handle with secure spring-clip latches.

Industry Standard: Our top-selling model for paint lines. In stock now.

"Superior Durability. Modular Maintenance. Maximum Longevity. — Redefining Thermal Profiling Standards."

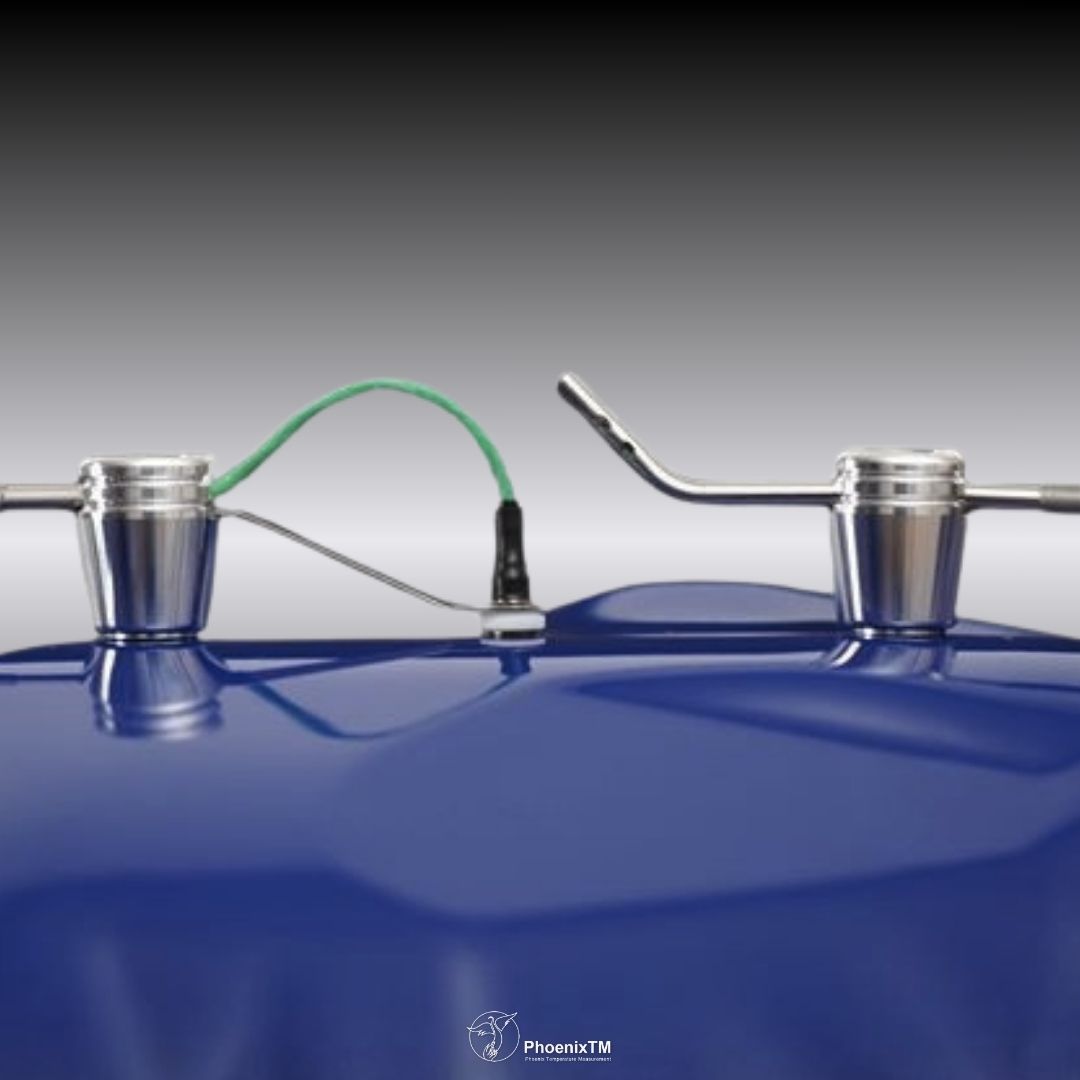

Thermocouples | High-Performance Sensors for the Finishing Industry

- High Accuracy: Built to ANSI MC96.1 Special Limits, guaranteeing precision of ±1.1°C or ±0.4% of reading.

- High Temp Support: Operating range up to 250°C—specifically optimized for the powder coating industry.

- High Savings: Modular Magnetic and Clamp probes allow you to replace only the cable if damaged, significantly reducing long-term maintenance costs.

| Probe Type (Function) | Product Code (2.0m) | Primary Application | Suitable Workpieces |

| Adhesive Patch | TC55-200-K | Fastest response for Product & Air | Ultra-thin parts, Cans, PCBs, Plastics |

| Exposed Junction | TC54-200-K | Multi-purpose Product & Air; durable & fast | Plastics, Composites, Taped or inserted sensing |

| Magnetic Surface | TC50-200-K | Measures Product Surface via magnetic attachment | Ferrous metals (Steel), 1.5mm thickness or more |

| Magnetic Air | TC51-200-K | Measures Oven Air near the product surface | Ferrous metals (Steel) |

| Clamp Surface | TC52-200-K | Measures Product Surface via edge clamping | Aluminum / Non-ferrous, 1.5mm thickness or more |

| Clamp Air | TC53-200-K | Measures Oven Air via edge clamping | Any workpiece with a clippable edge |

| Washer Probe | TC56-200-K | Screw-mount for repeat testing & high stability | Metallic parts, Tubular frames, 1.5mm+ thickness |

⚠️ Precision Matters: Using unsuitable probes poses a risk of equipment damage and undetected data inaccuracies. Not sure which one to choose? Contact our engineers for a free consultation.

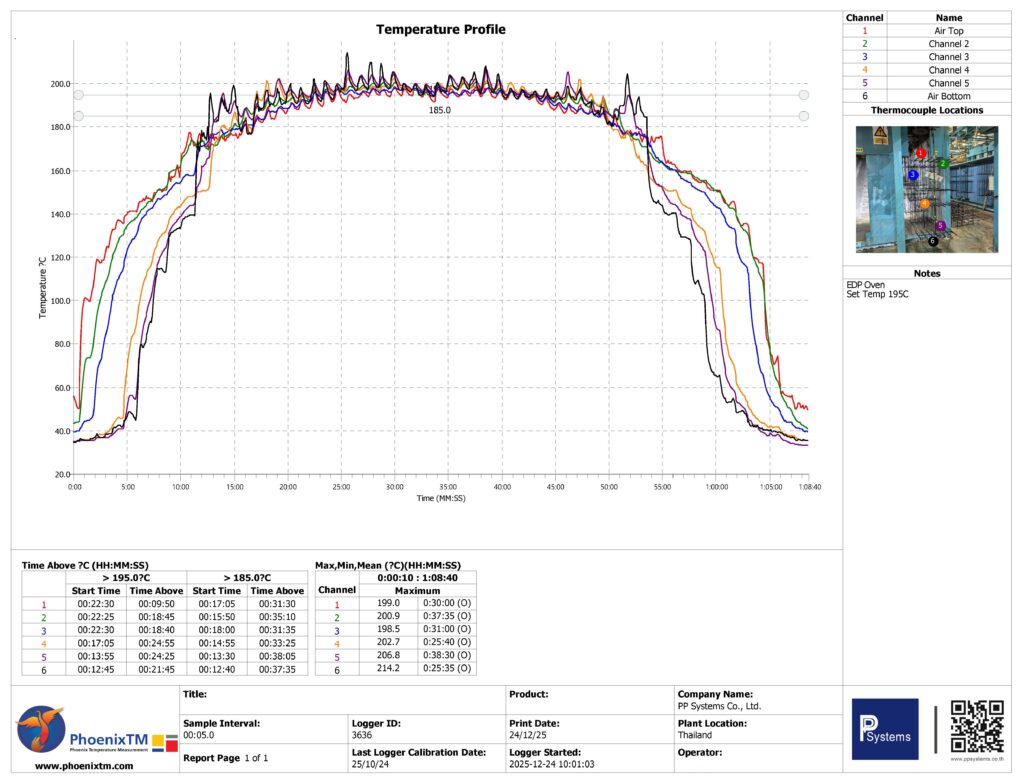

Thermal View Software | Intelligent Paint Curing Analysis

In the coating and finishing industry, “Time and Temperature” are the critical factors that determine whether paint will adhere perfectly or result in costly defects. The Thermal View Software is purpose-built to analyze the curing process, prioritizing simplicity and visual clarity above all else.

📈 Why Choose Thermal View for Your Coating Process?

Easy-to-use Simplicity: Designed for fast-paced production, Thermal View provides essential tools without unnecessary complexity. QC staff and technicians can learn the system and start profiling instantly.

Maximum Visual Clarity: The optimized interface maximizes the graph display area, allowing you to clearly identify the exact moment your product enters the Curing Window.

Time at Temperature Analysis: Instantly calculate Curing Time—the exact duration spent at the target temperature—to ensure full compliance with paint manufacturer specifications.

Smart Process Templates: Map your paint line layout directly in the software to link data with oven positions. Pinpoint Hot or Cold Spots with extreme precision for targeted adjustments.

🛡️ Maximum Confidence: Support & Expertise from PP Systems

At PP Systems, we pair superior tools with the right skills. Our support programs empower users to analyze coating results precisely and solve real-world production challenges.

Tailored Step-by-Step Training

We offer customized learning programs across three levels of professional mastery:

Level 1: Fundamentals – Master thermal parameters, logger configuration, and data management to ensure total data integrity.

Level 2: Graph Interpretation – Identify critical “Time at Temperature” data points to guarantee a perfect finish.

Level 3: Advanced Analysis – Evaluate oven efficiency and uniformity to ensure consistent quality in every batch.

Professional Reporting – Generate high-level reports compliant with Qualicoat, ISO, and CQI-12 to verify quality standards for your clients.

🔎 Continuous Online Support & Expert Review

We provide ongoing support to ensure your production remains seamless and error-free:

Data Verification: Our engineers provide online cross-checking to ensure your thermal profiles are accurate and reliable.

Remote Troubleshooting: Immediate software assistance via remote access minimizes downtime and keeps your operations running.

Online Refresher Courses: Keep your team sharp with sessions for new staff or updates on the latest Thermal View features.

Consulting for Improvement: We go beyond the numbers, offering actionable advice on adjusting temperatures or belt speeds to maximize efficiency and energy savings.

Turning Data into a Competitive Advantage Combining PP Systems’ expertise with PhoenixTM’s technology, we transform raw data into peak production standards every day.

"Continuous learning leads to superior results. Partner with us to elevate your team’s expertise and achieve total precision in every thermal profile."

กิจกรรมสัมมนาออนไลน์

1:30:56

2:18:49

1:11:01