Why Temperature Accuracy Matters in Oven Profiling?

When it comes to coating quality, consistent temperature monitoring through the curing oven is essential. The accuracy of your temperature profiling system determines the reliability of your data and, ultimately, the performance of your coating process.

What Is Cold Junction Compensation?

Understanding Thermocouple Theory

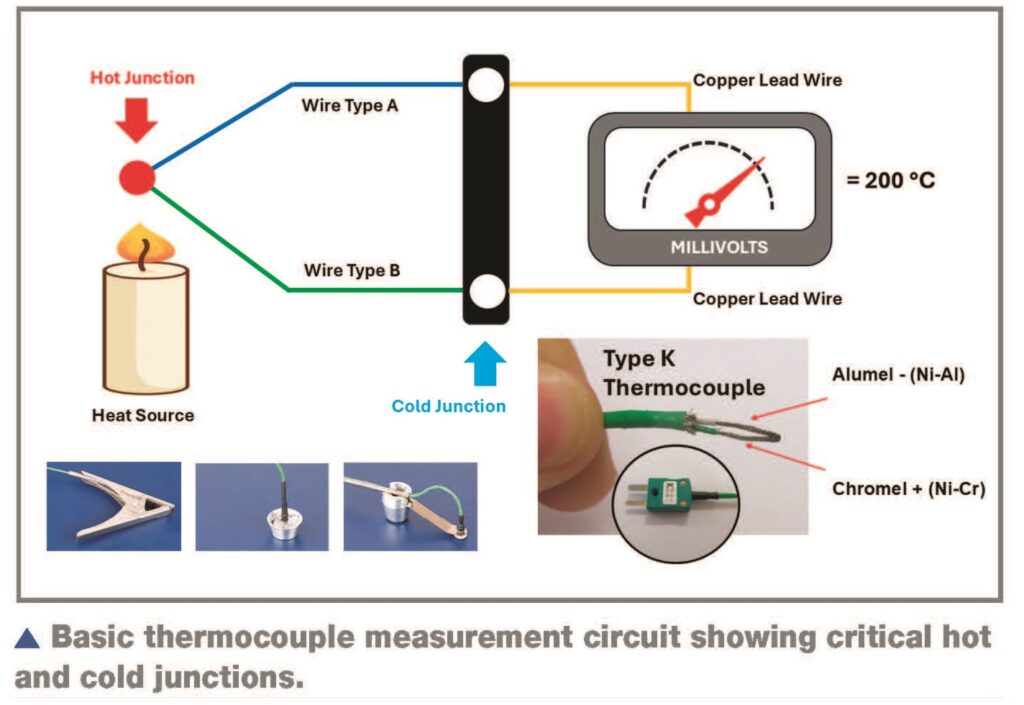

The thermocouple principle, discovered by Thomas Seebeck in 1821, describes how electricity is generated between two dissimilar metals depending on temperature. The resulting voltage can be converted to temperature using Seebeck voltage curves or thermocouple tables.

Hot vs. Cold Junction Explained

Many assume that only the hot junction determines accuracy, but the cold junction—where thermocouple wires meet the copper circuit—is equally critical. The cold junction temperature must be continuously monitored and compensated to ensure accurate readings.

How Cold Junction Compensation Works

Stable Accuracy Under Real Conditions

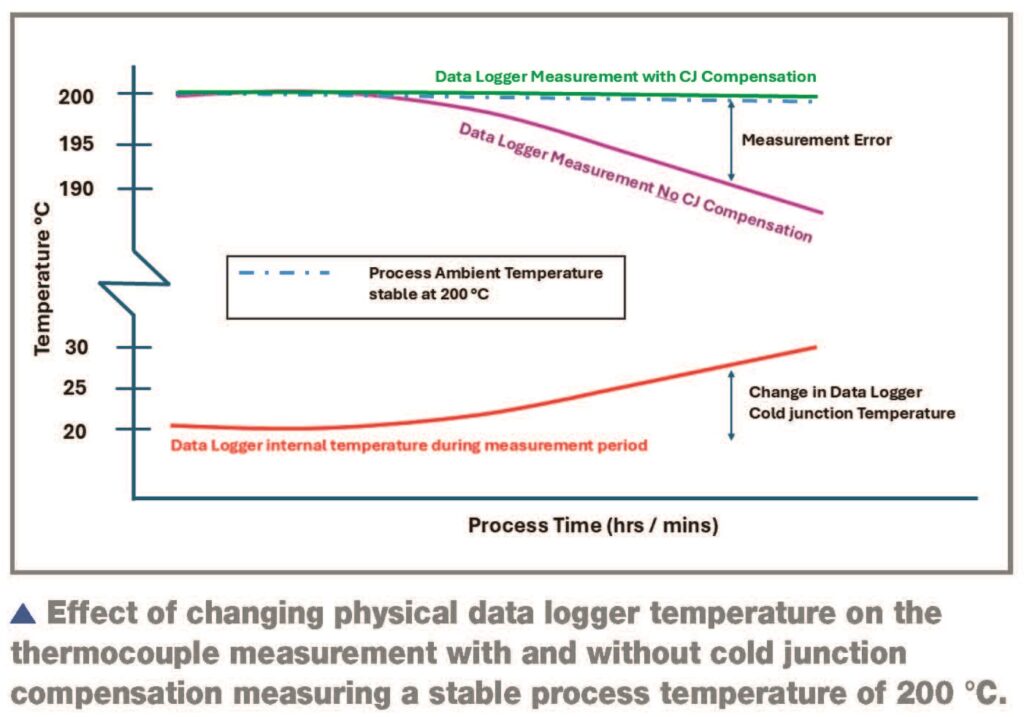

In laboratory calibration, accuracy may seem acceptable, but real-world conditions—where data loggers pass through ovens—can cause temperature instability. Effective Cold Junction Compensation ensures accuracy is maintained even as the data logger heats up.

PhoenixTM Cold Junction Technology

PhoenixTM data loggers feature precise Cold Junction Compensation sensors with ±0.3 °C accuracy across 0–80 °C. A thermistor inside the data logger cavity monitors junction temperature (+/- 0.1 °C), shielded from rapid environmental changes.

Data Logger and Thermocouple Correction Factors

PhoenixTM uses Type K thermocouples (ANSI MC96.1 “Special Limits of Error”) for ±1.1 °C accuracy. Combined with logger accuracy, the system achieves ±1.4 °C precision up to 250 °C.

The Thermal View Finishing software automatically applies correction factors from calibration files for both the logger and thermocouples, ensuring full-profile accuracy.

Conclusion

Find, Fix, and Forget with Confidence

PhoenixTM enables accurate, reliable temperature profiling—helping you identify and solve coating cure problems with complete confidence.

FAQ about Cold Junction Compensation?

1. What is Cold Junction Compensation?

Cold Junction Compensation (CJC) is a correction method used in thermocouple temperature measurement systems. It ensures that readings from the hot junction (sensor tip) are accurate by compensating for the temperature at the cold junction where the thermocouple connects to the data logger or measuring device.

2. Why is Cold Junction Compensation important?

Without Cold Junction Compensation, temperature readings can be inaccurate—especially when the data logger or connection point experiences temperature changes. Proper CJC ensures that the displayed temperature truly reflects the actual temperature of the measured object.

3. How does Cold Junction Compensation work?

A temperature sensor (usually a thermistor or RTD) is placed near the cold junction connection point. It continuously monitors the junction’s temperature, and the measurement system automatically applies a correction based on the thermocouple’s voltage-to-temperature curve.

4. What happens if Cold Junction Compensation is not accurate?

If the cold junction temperature is not measured correctly or fluctuates rapidly, the system will show incorrect temperature readings—sometimes off by several degrees. This can lead to poor process control, defective coatings, or failed quality checks in oven-cured processes.

5. How does PhoenixTM ensure accurate Cold Junction Compensation?

PhoenixTM data loggers are designed with precise internal thermistor sensors located in an isothermal cavity inside the logger. This design protects the sensor from rapid temperature changes and maintains accuracy of ±0.3 °C across the full 0–80 °C operating range, ensuring reliable real-world performance.

Reference

Surface World October 2025. (2025, October 29). Issuu. https://issuu.com/hillmedia25/docs/surface_world_october_2025